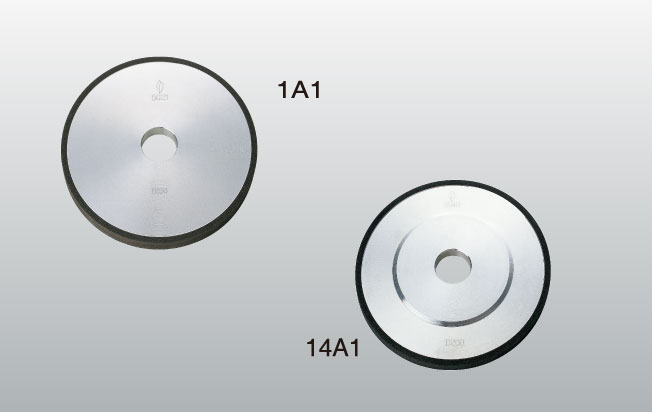

What are Diamond and CBN wheels

Understanding what diamond and CBN wheels are is very important because it can make a huge difference and convey amazing results every time. The best part about CBN wheels is that they can help with dry and wet precision grinding for a variety of hard materials. There are differences between CBN and diamond wheels however, and you need to identify those differences right away as it can be quite the difference.

CBN stands for cubic boron nitride. This is a highly abrasive compound that offers hardness very similar to what a diamond can deliver. Not only that, but you can work with ferrous compounds, which is not the case for a diamond. With that being said, you can also do cool cutting too. The diamond here is comprised out of pure carbon, and it’s created using high pressure and heat. When the diamond grinds hardened steel, it basically delivers a chemical reaction, generates graphite and loses strength.

That’s why you want to use a dedicated CBN wheel, because it doesn’t have carbon atoms. It’s made using nitride and boron, also using heat and pressure. These compounds can deliver high temperatures, but since CBN offers great thermal conductivity it can stay cool without dealing with any issues like losing heat.

Because of that, a CBN wheel can be highly efficient for grinding, and it certainly gets the job done in a very good manner. With that being said, you can use a CBN wheel for nickel alloys, high speed steels, tool steels, stellite and machining any kind of hardened steel.

As the name suggests, this is a wheel that harnesses the power of diamonds to sharpen or grind a variety of materials. This can be very good if you want to work with things like non ferrous metals, ceramics, glass, carbide, ferrite and many others. The main reason why you want to use a diamond wheel is because it delivers a very good hardness. The quality is incredible and you will appreciate the great value and experience presented here. On top of that, you have other features like thermal conductivity.

Why is this important? Thanks to the thermal conductivity, the crystal is able to transfer heat from the cutting edge of the wheel and, as needed, it can dissipate the energy properly. You can use these for graphite, sapphire glass, hard faced alloys and carbides, among many other categories.