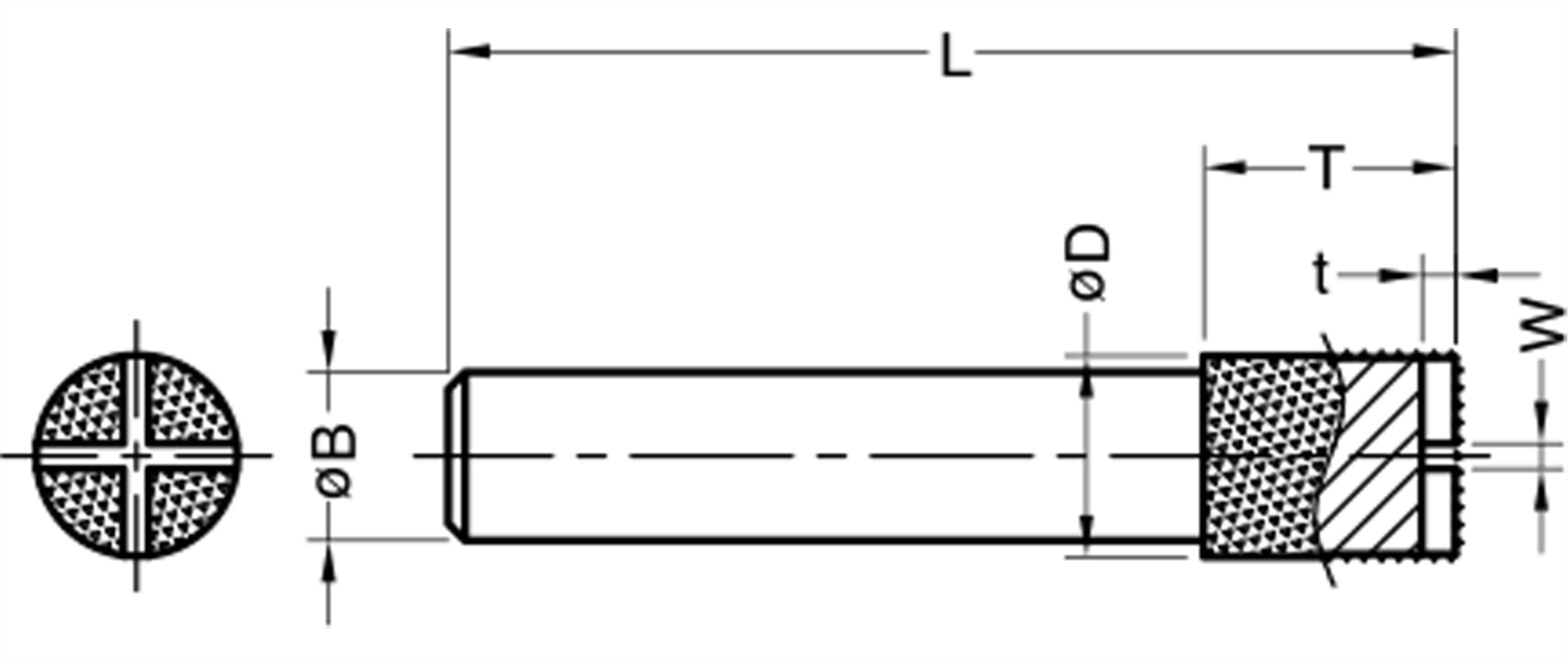

Brazing Milling Tools

Description

Description

Brazing Milling Tools

Applications: Milling, grinding and drilling ceramics, alumina, silicon carbide, quartz, granite, non-metallic materials.

Features: Good heat resistance, sharpness better than metal. Suitable for large allowance and fast milling.

Specifications

Specifications

Common specifications

Unit: mm

|

Order No. |

ØD |

T |

ØB |

L |

W |

t |

Grit size |

Material |

|

VBZ3 |

3 |

10 |

6 |

50 |

0.5 |

1 |

D80 |

Medium-carbon steel |

|

VBZ4 |

4 |

10 |

6 |

50 |

0.5 |

1 |

||

|

VBZ5 |

5 |

10 |

6 |

50 |

1 |

1 |

||

|

VBZ6 |

6 |

12 |

6 |

50 |

1 |

1 |

||

|

VBZ8 |

8 |

12 |

8 |

50 |

1.5 |

1.5 |

||

|

VBZ10 |

10 |

15 |

10 |

60 |

1.5 |

1.5 |

Free-cutting steel |

|

|

VBZ12 |

12 |

15 |

10 |

60 |

1.5 |

1.5 |

||

|

VBZ16 |

16 |

20 |

10 |

80 |

2 |

2 |

||

|

VBZ20 |

20 |

20 |

10 |

80 |

2 |

2 |

||

|

VBZ25 |

25 |

20 |

16 |

80 |

2 |

2 |

||

|

VBZ30 |

30 |

20 |

16 |

80 |

2 |

2 |

Some dimensions are make-to-order. Ask before making a purchase. Offer other specifications according to your drawing or sample.

Features

Features

Key Features

High rigidity & stability – Brazed carbide tips and robust shank ensure stable cutting even under heavy loads.

Excellent wear resistance & long tool life – Carbide tips are treated for durability and high temperature resistance, ideal for high-volume production.

Variety of cutter types and sizes – End mill, ball nose, slot mill and more to match different processing needs.

High cutting efficiency & superior finish – Fast material removal with good surface quality, reducing downstream finishing work.

Wide material compatibility – Aluminum alloys, steel, stainless steel, copper alloys, and general metal parts.

Applications

Applications

Automotive components (joints, gears, housings, etc.)

Aerospace and metal structural parts

Mass production of metal parts made from steel, aluminum, stainless steel, etc.