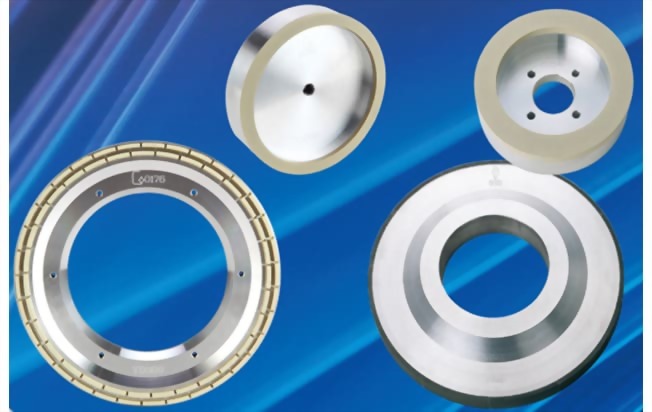

Vitrified bond diamond wheels

Description

Description

Resin bond diamond wheel and metal bond diamond wheel have played a very important role in the working of traditional materials (e.g. stone, TC, hardened steel, glass, etc.).with the rapid growth of semiconductor industry and the development of automatic processing, apparently, they cannot meet all the demands of new technics and precision work to some new materials. CP DIAMOND is always keeping to developing vitrified bond diamond wheels which are used to the semiconductor industry and the motor industry. Now we have many kinds of products which have been successfully applied to many new materials and technics for various customers. Hereunder are our specifications for your reference.

|

D(mm) |

T(mm) |

X(mm) |

H(mm) |

Grit size |

Application |

|

152 |

10 |

5 |

31.75 |

D150/B150 |

Split punch, precision machine parts, bearing to target coated by hard layer, etc. |

|

175 |

10 |

5 |

31.75 |

D150/B150 |

|

|

300-600 |

15-40 |

5 |

127 |

B150 |

|

|

660 |

50 |

5-10 |

205 |

D300 |

Hard coated layer grinding of parts such as injection machine charging ram |

|

D(mm) |

W(mm) |

X(mm) |

H(mm) |

Grit size |

Application |

|

150 |

3-20 |

5-10 |

40 |

D200-1200 |

Diamond & PCD lathe tools |

|

150 |

3-10 |

5-10 |

M12*1.75 |

D300-3000 |

GaAs & sapphire |

|

254 |

4 |

8+1 |

155 |

D300-3000 |

Recycle of silicon wafers |

|

D(mm) |

W(mm) |

X(mm) |

H/T(mm) |

Grit size |

Application |

|

125 |

8 |

4 |

31.75/35 |

D300/600 |

PCD lathe tools |

Note: standard grit size. Others depend on your requests.

Please indicate the following information when placing a new order.

1 specification

2 quantity

3 other requirements